Descrição do Produto:

I. Atributos Básicos de Funcionamento

Princípio de Funcionamento

Com base na tecnologia de jato de pulso, ele libera instantaneamente ar comprimido através de controle eletromagnético ou pneumático para formar um fluxo de ar de pulso de alta velocidade, que limpa as mangas/cartuchos de filtro e remove a poeira aderida.

Métodos de Controle

Controle eletromagnético: A porta da válvula é aberta/fechada rapidamente pela válvula solenóide que recebe sinais elétricos, com uma velocidade de resposta rápida (nível de milissegundos).

Controle pneumático: Acionado por uma válvula de controle pneumático, é adequado para ambientes de alta pressão e severos (como ocasiões de alta temperatura e corrosivas).

II. Parâmetros Técnicos Essenciais

Pressão de Trabalho

Normalmente 0,4-0,7MPa (modelos especiais podem se adaptar a pressões mais altas). A estabilidade da pressão afeta diretamente a força de sopro e o efeito de limpeza de cinzas.

Volume de Sopro e Tempo de Sopro

Volume de sopro: A quantidade de ar comprimido liberada em um único momento (relacionado ao diâmetro da porta da válvula e à pressão), que precisa corresponder ao tamanho da manga/cartucho do filtro.

Tempo de sopro: Geralmente 0,05-0,2 segundos, que pode ser ajustado através do sistema de controle. Se for muito curto, a limpeza de cinzas será incompleta; se for muito longo, a energia será desperdiçada.

Tempo de Resposta

O tempo desde o recebimento do sinal até a abertura total é geralmente ≤50 milissegundos. Uma resposta rápida pode reduzir a perda de ar comprimido e aumentar a frequência de limpeza de cinzas.

Tamanho da Interface

Os diâmetros dos tubos de entrada e saída de ar (conectados ao tubo de sopro). As especificações comuns incluem DN20, DN25, DN32, etc. (ou especificações em polegadas 1/2", 3/4", etc.), que precisam corresponder ao encanamento do sistema.

Meio de Trabalho

Ar comprimido seco e limpo (teor de óleo ≤0,5ppm, teor de água ≤-40℃ ponto de orvalho) para evitar o bloqueio ou corrosão do corpo da válvula por impurezas.

III. Atributos de Adaptabilidade Ambiental

Temperatura de Trabalho

Modelos regulares: -10℃~60℃ (controlado eletromagneticamente).

Modelos de alta temperatura: Podem se adaptar acima de 150℃ (precisa usar materiais de vedação e materiais do corpo da válvula resistentes a altas temperaturas).

Resistência à Corrosão

O material do corpo da válvula pode ser ferro fundido, liga de alumínio (com tratamento anti-corrosão superficial) ou aço inoxidável (304/316). Os modelos de aço inoxidável são adequados para ambientes úmidos e corrosivos (como indústria química e indústrias de incineração de resíduos).

Nível de Proteção

O nível de proteção da parte da bobina eletromagnética é geralmente IP65 (à prova de poeira e protegido contra pulverização de água de baixa pressão), e alguns modelos podem atingir IP67, adaptando-se a condições de trabalho com mais poeira.

IV. Atributos Estruturais e de Material

Estrutura do Corpo da Válvula

Adota uma estrutura de diafragma (o componente principal é um diafragma elástico). A porta da válvula é aberta/fechada através da rápida deformação do diafragma, que possui as características de boa vedação, baixo desgaste e longa vida útil.

Material do Diafragma

Os materiais comuns são borracha nitrílica (NBR, resistente a óleo e ao desgaste) e borracha fluorada (FKM, resistente a altas temperaturas e à corrosão química). A seleção depende do meio de trabalho e da temperatura.

Parâmetros Técnicos:

online)

Princípio de Funcionamento

Principais Características

1) Estrutura simples em tipo linear, fácil de instalar e manter.

2) Adotando componentes de marca mundialmente famosa em peças pneumáticas, peças elétricas e peças de operação.

3) Virabrequim duplo de alta pressão para controlar a abertura e o fechamento da matriz.

4) Funcionando em alta automatização e intelectualização, sem poluição

5) Aplique um conector para conectar com o transportador de ar, que pode ser diretamente em linha com a máquina de enchimento.

Desenho de Dimensão

Aplicações:

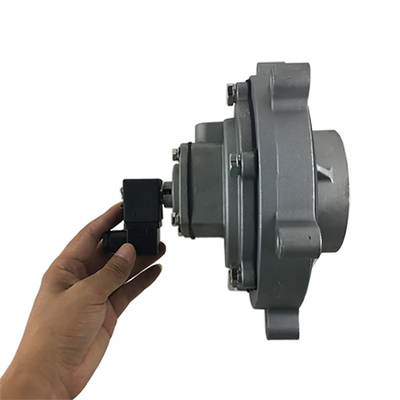

As Válvulas de Jato de Pulso, também conhecidas como válvulas de pulso pneumáticas, são componentes versáteis que encontram aplicação em várias indústrias e cenários. As Válvulas de Jato de Pulso da marca TURBO, originárias da China e detentoras da certificação CE, são produtos confiáveis e de alta qualidade, adequados para uma ampla gama de usos.

Essas válvulas de pulso são essenciais em cenários onde há necessidade de controle eficiente do fluxo de ar limpo. Com um corpo de válvula feito de liga de alumínio fundido, elas oferecem durabilidade e desempenho confiável, mesmo em ambientes desafiadores. O grau de proteção IP65 garante que as válvulas sejam protegidas contra poeira e umidade, tornando-as adequadas para aplicações internas e externas.

A faixa de temperatura ambiente de -30°C a +40°C aprimora ainda mais a adaptabilidade dessas Válvulas de Jato de Pulso, permitindo que funcionem efetivamente em várias condições climáticas. Operando em uma faixa de pressão de 0,1 a 0,8MPa, essas válvulas são capazes de atender aos requisitos de diferentes sistemas pneumáticos.

Seja em ambientes industriais, fábricas, sistemas de coleta de poeira ou outras aplicações pneumáticas, essas Válvulas de Jato de Pulso da TURBO podem ser integradas perfeitamente para aumentar a eficiência operacional. A quantidade mínima de pedido de 1 e as opções de preços flexíveis por meio de negociação tornam essas válvulas acessíveis a empresas de todas as escalas.

Com opções de embalagem, incluindo caixa de papelão ou personalização de acordo com os requisitos do cliente, o tempo de entrega de 1 a 7 dias úteis após o pagamento garante a disponibilidade rápida das válvulas. Os clientes podem escolher entre métodos de pagamento como T/T, Western Union e Paypal, adicionando à conveniência de aquisição.

Com uma capacidade de fornecimento de 5000 peças por mês, as empresas podem contar com uma disponibilidade constante dessas Válvulas de Jato de Pulso de alto desempenho para atender às suas necessidades operacionais de forma eficaz. Seja para novas instalações ou substituição de válvulas existentes, as Válvulas de Jato de Pulso TURBO oferecem uma solução confiável para controlar o fluxo de ar em sistemas pneumáticos.

Embalagem e Envio:

Esta Válvula de Jato de Pulso é cuidadosamente embalada para garantir sua entrega segura a você. A válvula é colocada com segurança em uma caixa de papelão durável com acolchoamento de espuma protetora para evitar qualquer dano durante o transporte.

Para envio, fazemos parceria com transportadoras confiáveis para entregar seu pedido de forma rápida e eficiente. Sua Válvula de Jato de Pulso será enviada com cuidado para chegar até você em perfeitas condições.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!